Product Carrier Redesign

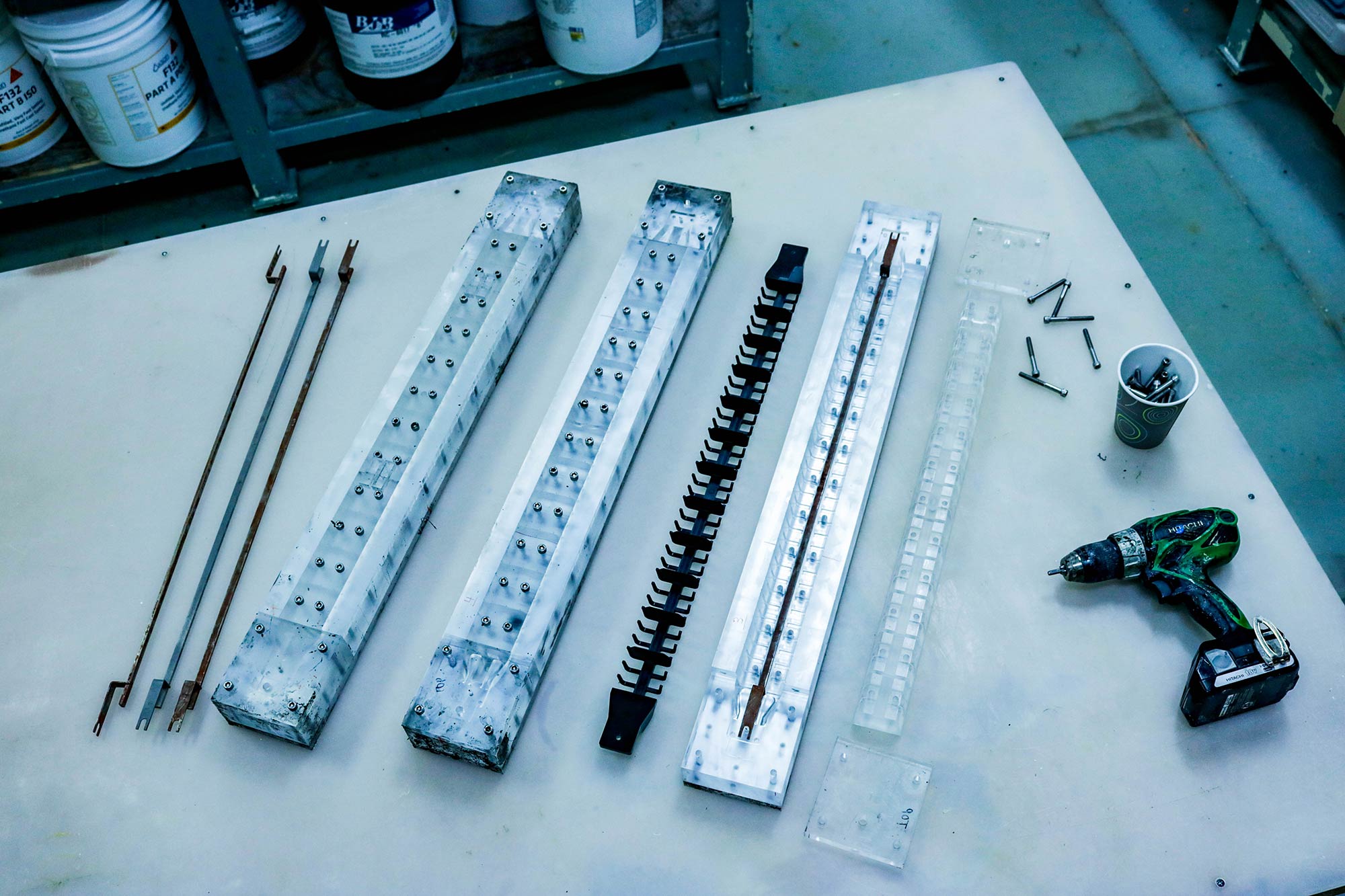

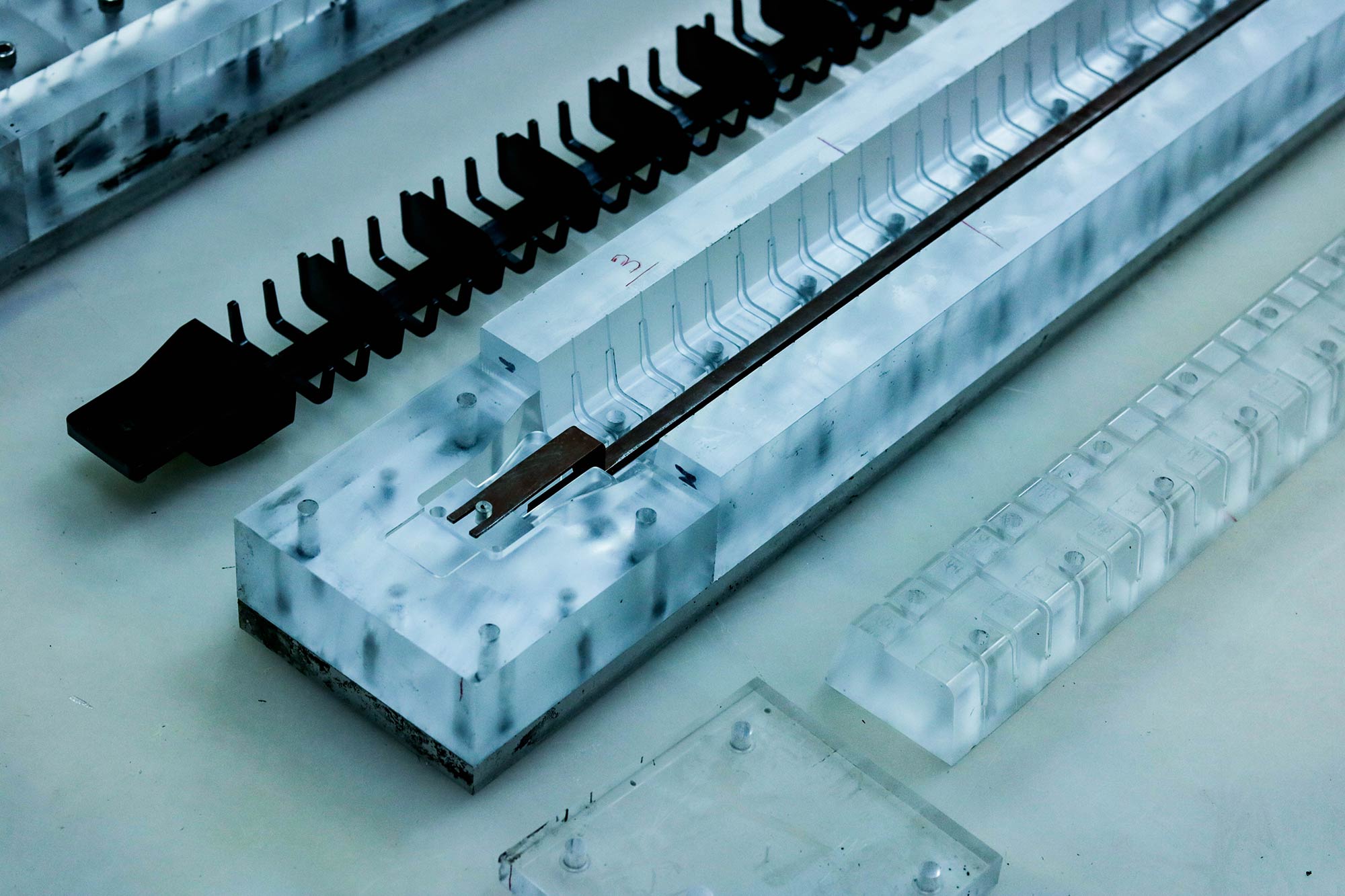

CAD / CNC Machining / Urethane Casting / Short Run Production

A leading consumer product company had been experiencing problems on a product packing line. When a crash occurred, the rigid ABS plastic product carriers were being broken. This resulted in significant downtime, loss of product and replacement expense.

The Challenge: Modify the product carrier to reduce the loss of product, time and money in the event of a crash.

That’s where we came in!

The Solution: We helped redesign the product carrier to incorporate a metal frame encapsulated in a 95A durometer thermoset elastomer.

Happy Customer: The flexible thermoset elastomer not only eliminated damage during a packing line crash by bending rather than breaking, but also out performed an injection molded elastomer option for chemical resistance when exposed to the liquid product.