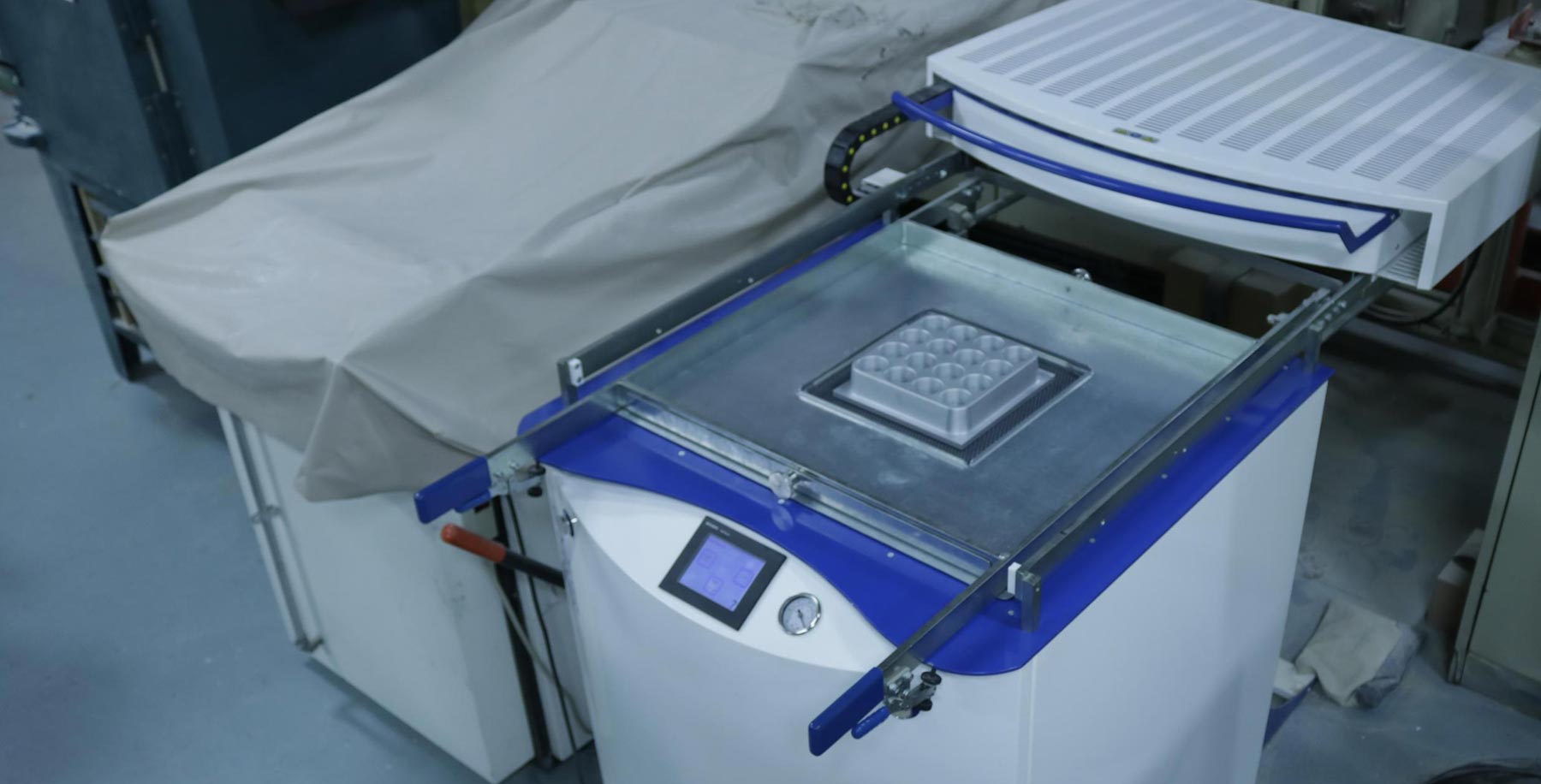

Vacuum Forming is a method of thermoforming plastic to create a wall thickness part. The plastic sheet is heated to forming temperature, then stretched on to the tooling while vacuum is applied which pulls the plastic tight against the tooling. When the plastic cools it takes the shape of the tool. The part is then trimmed and any secondary machining operations are performed. 3-D Technical Services uses this process to create the housings for our medical training devices and transparent blister packaging prototypes for a variety of consumer products. We have multiple machines capable of a 12″ x 12″ thru 4′ x 6′ blank from .010″ – .250″ thick.

Innovative Solutions

Innovative Solutionsfor Models and Prototypes Menu