Thermoforming

Advanced Capabilities for Complex Prototyping Requirements

Extensive Thermoforming Solutions for Custom-Shaped Components

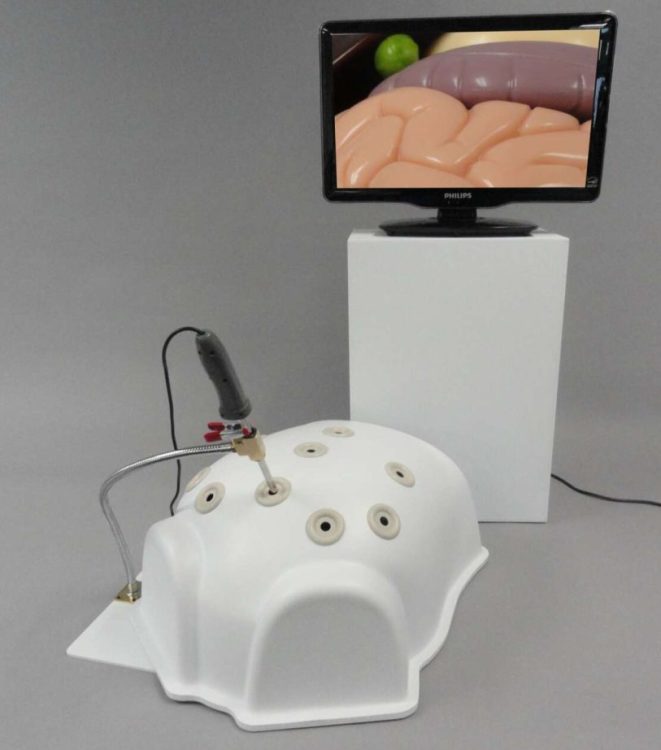

3-D Technical Services has exceeded customer expectations for almost 40 years, developing lasting partnerships that foster mutual success. This success has allowed us to invest in the latest technologies and advanced thin-gauge thermoforming capabilities that enable us to provide high-quality, precision components and custom packaging prototypes. Leveraging extensive industry experience and advanced software, our highly skilled experts work closely with our customers to help streamline product and tooling designs for optimal production and profitability.

We have multiple machines that use a combination of heat and vacuum to mold the material onto the surface of the customized tool. These machines are capable of creating quality components and durable consumer packaging in a 12″ x 12″ through 4′ x 6′ blank between .010″ and .250″ thick.

In-House Tooling and Secondary Process Capabilities

3-D Technical maintains extensive in-house fabrication capabilities, ranging from precision CNC machining to laser cutting, allowing us to create tooling customized to meet your project’s specifications. Even the most precision-engineered product produced by the thermoforming process will typically have extra material along the seams that needs removing for proper fit and function. To ensure precision and quality, we maintain comprehensive secondary capabilities ranging from hand trimming to custom labeling and graphics. By keeping tooling production and secondary processes in-house, we can reduce costs and lead times, ensuring high-quality components and functional prototypes are delivered on time.

Material Capabilities

- Polyethylene terephthalate glycol (PETG): Transparent and impact-resistant

- High-impact polystyrene (HIPS): Versatile and malleable, odorless and non-toxic

- Acrylic (PMMA): Transparent, impact- and chemical-resistant

- Acrylonitrile Butadiene Styrene (ABS): Durable and versatile, variety of colors

Integrated Manufacturing for Prototype to Short-Run Production

3-D Technical Services has worked with customers across industries to develop high-quality, functional prototypes, tradeshow models, marketing tools, and more. We have had the opportunity to continuously improve and enhance our capabilities, allowing us to meet the needs of our customers. These extensive capabilities also allow us to seamlessly transition from prototyping to short-run/low-volume production when the expense of permanent tooling isn’t viable.

Why Choose 3-D Technical Services for Thermoforming Prototypes?

We leverage almost 40 years of experience with industry-leading technologies to rapidly produce high-quality plastic products and consumer packaging prototypes with extreme detail and complexity. Customer service excellence at 3-D Technical means prompt responses and ongoing collaboration. We aim to accelerate your product development with expert services delivered on time.

Contact us today to find out more about our thermoforming services.